The making process of a Clear Glass Table Top generally involves the following steps:

1. Raw Material Preparation

High-quality silica sand, soda ash, limestone, and other additives are carefully measured and mixed in specific proportions. This mixture forms the base material for glass production.

2. Melting

The prepared raw materials are fed into a high-temperature furnace, typically heated to around 1500 – 1600°C. Under such extreme heat, the solid mixture gradually melts into a viscous liquid state, ensuring homogeneity and eliminating any impurities.

3. Shaping

Once the glass is in a molten state, it is poured or drawn into a circular mold. The mold is precisely designed to achieve the desired diameter and thickness of the table top. Gravity and sometimes additional shaping tools are used to ensure the glass spreads evenly and takes on the perfect round form.

4. Annealing

After shaping, the newly formed glass table top is still under internal stress. It is then slowly cooled down in a controlled annealing oven. This process helps relieve the stress, preventing the glass from cracking or shattering during subsequent handling and use. The cooling rate is carefully regulated, usually taking several hours to complete.

5. Polishing

To achieve a smooth and clear finish, the annealed glass table top undergoes a polishing process. Specialized polishing machines with abrasive pads of varying grits are used to grind away any surface imperfections, scratches, or roughness. This step is crucial for enhancing the visual appeal and tactile quality of the final product.

6. Quality Inspection

Before leaving the factory, each Clear Round Glass Table Top is meticulously inspected. Technicians check for any remaining defects, such as bubbles, inclusions, or uneven thickness. Only those that meet strict quality standards are packaged and prepared for shipment.

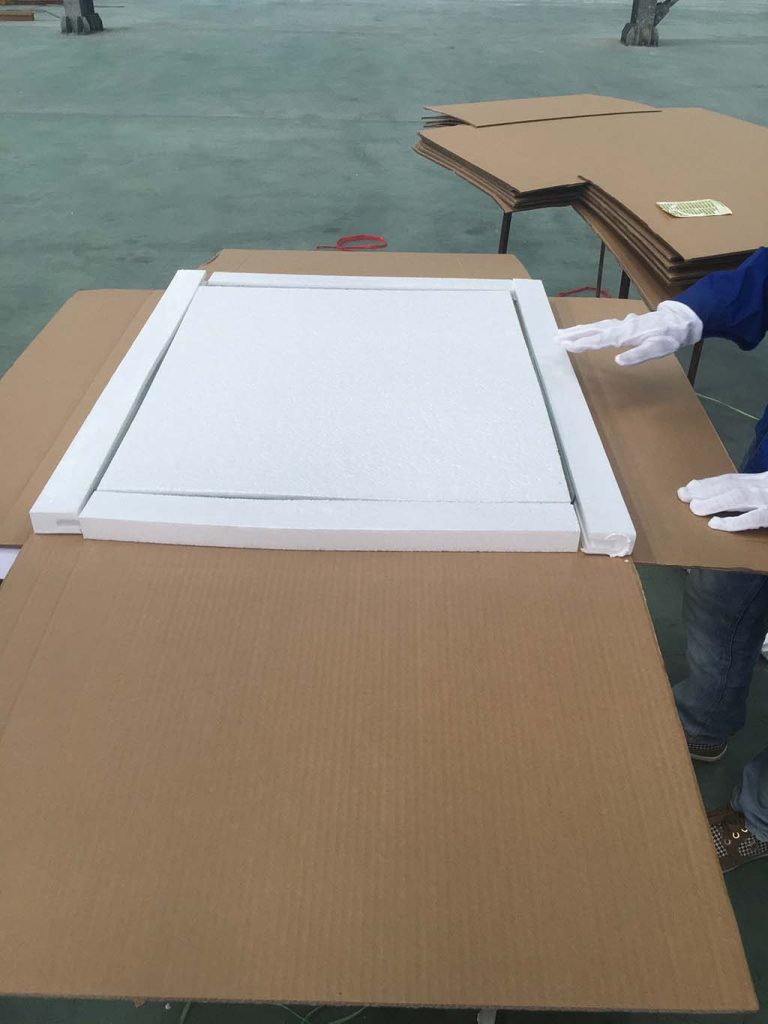

7. Packaging

Qualified table tops are carefully wrapped in protective materials like bubble wrap and placed in sturdy cardboard boxes or wooden crates, depending on the size and fragility, to ensure they reach customers in perfect condition.